INDUSTRIAL PAINTING: What is it?

Industrial painting refers to the process of applying coatings to surfaces used in industrial settings. This is done for a variety of reasons, including improving the appearance of surfaces, protecting surfaces from environmental damage, and preventing rust and corrosion.

Industrial painting can be done on a variety of surfaces, including concrete, metal, wood, and plastic. However, the most common surfaces that require industrial painting are industrial tanks, heavy machinery, industrial equipment, and grain silos.

Benefits of Industrial Painting

There are many benefits of industrial painting. First and foremost, it protects surfaces from environmental damage, such as exposure to sunlight, water, and chemicals. This helps to extend the life of equipment, which is essential in industrial settings where machinery and equipment are a significant investment.

In addition to protection, industrial painting can also improve the appearance of surfaces, making them more aesthetically pleasing. This is especially important for businesses that interact with the public, as it can enhance the company’s image and reputation.

Industrial painting can also help to prevent rust and corrosion, which can cause equipment to fail prematurely. This is critical in industrial settings where downtime can be costly and disruptive.

Types of Surfaces That Require Industrial Painting

As mentioned earlier, the most common surfaces that require industrial painting are industrial tanks, heavy machinery, industrial equipment, and grain silos. Let’s take a closer look at each of these surfaces.

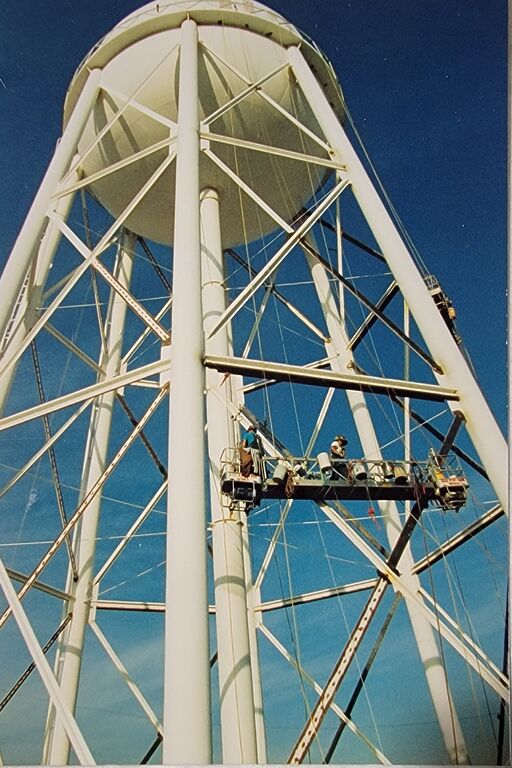

Industrial Tanks

Industrial tanks are used to store liquids, such as water, oil, and chemicals. These tanks are typically made of metal or concrete and are subject to environmental damage, including rust and corrosion. Industrial painting helps to protect these tanks from damage and extend their lifespan.

Heavy Machinery

Heavy machinery, such as bulldozers, cranes, and excavators, are used in construction and manufacturing. These machines are subject to wear and tear, which can cause them to fail prematurely. Industrial painting can help to protect these machines from environmental damage and prevent rust and corrosion.

Industrial Equipment

Industrial equipment, such as conveyor belts, pumps, and turbines, are critical to the operation of industrial facilities. These machines are subject to wear and tear and can fail if not properly maintained. Industrial painting can help to protect these machines from environmental damage and extend their lifespan.

Grain Silos

Grain silos are used to store grain for human and animal consumption. These silos are typically made of metal and are subject to environmental damage, including rust and corrosion. Industrial painting can help to protect these silos from damage and extend their lifespan.

In Conclusion

Industrial painting is a critical aspect of maintaining and protecting heavy machinery, industrial tanks, equipment, and grain silos. It offers many benefits, including protection from environmental damage, improved appearance, and prevention of rust and corrosion. If you operate an industrial facility, it’s essential to ensure that your equipment and surfaces are properly painted to ensure their longevity and optimal performance. Contact Kaz to schedule a walkthrough of your industrial property.